The manufacturing industry is still alive and kicking in western nations such as the United States, and despite the economic woes that have affected many countries around the world, the tide is finally starting to change and people (businesses) are learning their lessons from their past mistakes.

When you make something, you obviously need to have a significant investment in your infrastructure and do things as efficiently as possible, so that you don’t waste any time, money or resources. Having said that, a sad statistic of American manufacturing is that a lot of companies still don’t do things efficiently, and are just generally wasting too much stuff!

The news isn’t all bad, however. It is actually perfectly possible to make a few changes to a factory production line in order to make the process smoother and efficient.

I know that a lot of companies such as Amazon invest millions of dollars each year into improving their warehouse facilities, as well as for their own product manufacturing facilities, but the good news is that you don’t necessarily need to spend such vast sums of money to do the same thing!

Intrigued? Here’s how!

Planning

Any successful project requires a great deal of planning. If you skip this essential component of design for any factory production line, you will end up paying for it later – in more ways than one!

You should be thinking about what your goals are for the production of your items, such as whether you only want to produce a small or large volume of items, what other facilities you want to put in place within the immediate area, and how many staff you are planning on employing for your production line.

Deployment

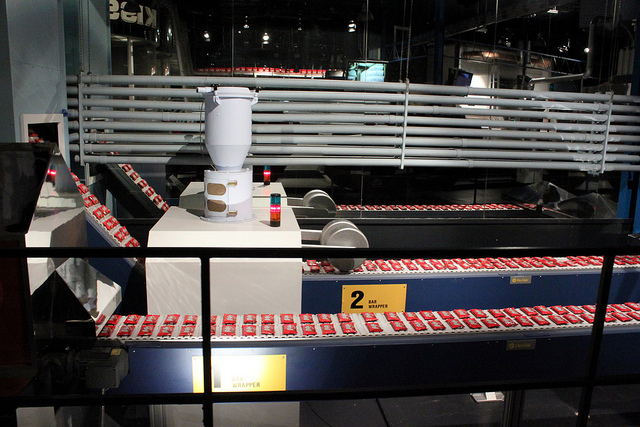

All factory production lines require bespoke equipment in order to operate efficiently; this is because there are no “out of the box” solutions available to suit a wide range of purposes.

Factory owners generally have to buy machinery, equipment, tools and other items from a number of different suppliers to achieve the desired end result – a production line that is easy to manage, operate and maintain.

For example, certain things like conveyors might need certain steel supports made from a fabrication shop Alabama in order to set up a level conveyor system across uneven ground, or perhaps bespoke lighting systems might need to be incorporated in certain areas where strong illumination is required for the purposes of inspecting items that have just been manufactured.

Training

A big problem for a lot of factory owners is not always necessarily down to equipment or machines being incorrect or not fit for purpose, but the people that operate them.

In order for a company’s production line to run as smoothly and efficiently as possible, staff need to be trained properly so that they know what they are doing, and you can have peace of mind knowing that they can work unsupervised without causing problems to other parts of the production line chain – or injury to themselves.