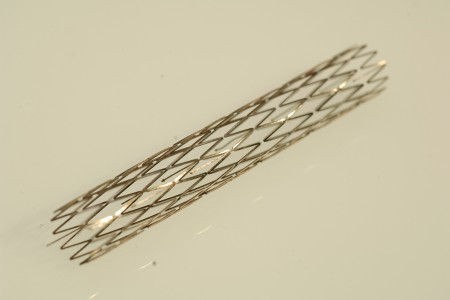

Laser micro-machining is the most effective and precise way to cut small hardware parts for vital use in important industries, from aerospace to medical devices. Astoundingly, a laser cutter has the ability for high precision cutting with thicknesses ranging from 3mm to 2µm (micrometers).

The machines are extremely powerful, cutting through steel, stainless steel and other alloys through the use of a laser. They can also carry out laser drilling, marking or welding.

Below are the general steps from concept to production for high-precision micro parts:

-

Assess your needs

The first step towards using any form of laser micro-cutting is to assess your needs. Parts created through this process are meant to be excessively detailed-oriented, even in their micro form.

They are usually used for extremely demanding and precision-requiring sectors such as for aerospace, nuclear and medical sectors or even watches. Thus, the development process carries a heavy burden: a small imbalance or imprecision can be dangerous.

In this regard, their precision in shape, consistency and cut is absolutely vital, and all measurements and material needs should be pre-researched and confirmed before the process takes part.

-

Create a design

The design process must be handled by a professional engineer with proficiency in micro-engineering.

Using a specialized software, they must create a precise design to be cut from the material.

The design must take into account the material type, dimensions, specifications for the laser cutter, and be precise in the component’s visual design.

-

Use a laser cutting machine

Creating microscopic or extremely tiny hardware requires use of laser micro-machining equipment.

This machinery is custom designed and is not available everywhere. However, with today’s accessibility to the internet, finding the appropriate machinery for rent or purchase has become easier, and designs or concepts can be sent by e-mail.

Laser micro-machining must be done only through the use of highly efficient, high quality and properly kept laser cutting machines.

They must only be run by experts with experience and knowledge to use the machine safely and properly.