Control is a key factor in any type of operation where the primary goal is to garner profits. Whether it is command over expenditures, tool, personnel, market forces or even one’s own ability to respond to the desires of customers, control is necessary in order for the “machine of industry” to function properly.

In manufacturing, the idea of applying Agile methodologies has increased the ability of certain organizations to apply their best attributes in the most efficient manner for each situation. Given that most large-scale manufacturing operations involve individuals of different levels in all departments, it isn’t always easy to deal with the needs of customers directly. For example, a common problem in manufacturing (where non-agile methods are employed) is dealing with issues before they’re allowed to travel “downstream”, so to speak.

What is meant by the term “downstream”? If you can imagine the entire manufacturing process as a conveyor belt (this would include everything from concept, design, tooling and accountability to production, marketing, and perhaps even sales), it’s easy to see how problems existing in the initial stages will only become exacerbated as they travel down the line. One of the main tenets of Agile Manufacturing is to deal with any and all potential problems and issues as early as possible; in doing so, a company will not only save money and time, but they might also prevent profit loss due to customer dissatisfaction (in terms of overall quality).

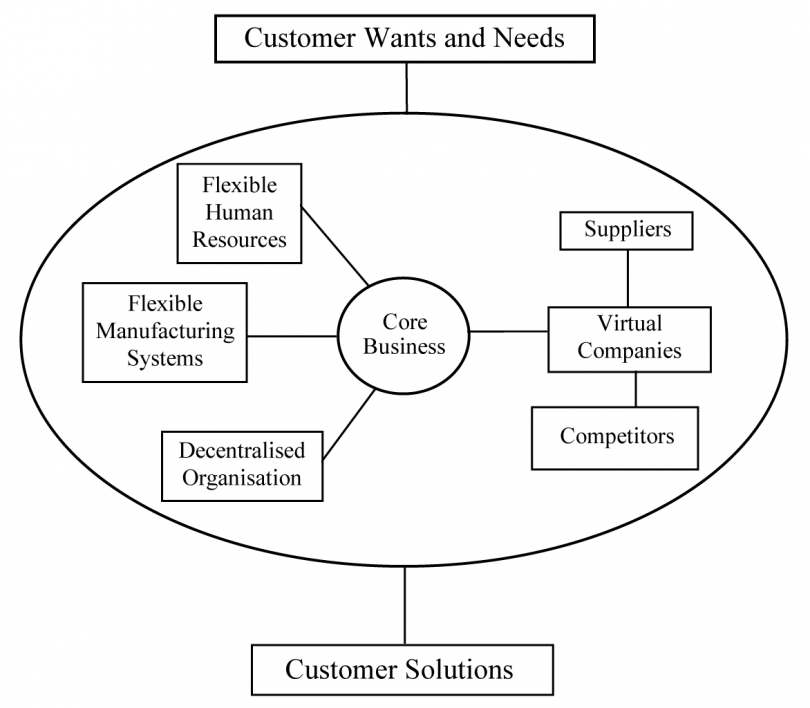

How is more efficient production achieved through Agile Manufacturing, you ask? By creating a more centralized system whereby a greater number of individuals (involved in any particular project) can access specific details and information covering production capacity, available products, and notes on any and all troubles, solutions can be enacted earlier. In other words, problems can be solved or completely avoided while at the same time, virtually anyone at any stage of the manufacturing operation can see what’s going on much more clearly. The end result is that customers receive products which work better and are perhaps more suited to their needs. Additionally, the Manufacturer who practices Agile methods is saving vast sums which might have been erased due to mistakes, while at the same time they are increasing their overall efficiency in every direction.